Bicomponent Fabric Manufacturing Canada

Mogul manufactures with advanced bicomponent polyester spunbond technology to extrude filaments with two distinct cross-sectional geometries: (1) round core and sheath, and (2) tipped trilobal.

- Buffalo Round Core and Sheath:

- Core: PET

- Sheath: CoPET

- Buffalo Tipped Trilobal (TCS):

- Core: PET

- Lobes’ Tips: CoPET

The incorporation of CoPET with a lower melt temperature in the filaments enhances fiber-to-fiber bonding. In comparison to conventional flat-bonded PET spunbond, Buffalo demonstrates superior CD tensile strength, abrasion resistance, and internal bonding. Mogul’s Buffalo bi-component PET stands out as a unique and premium product due to its limited industry technology and a scarcity of suppliers.

Moreover, Mogul ensures that the polyester resins received adhere to food contact regulations, meeting the FDA 21CFR-1771630 standards. This commitment to regulatory compliance underscores the quality and safety of Mogul’s polyester resins.

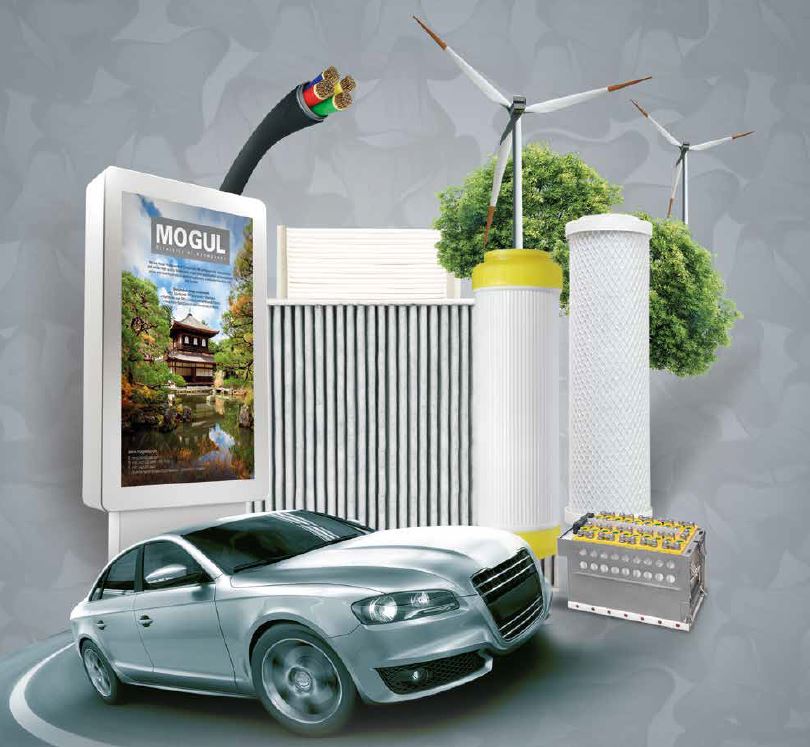

Bicomponent Fabric Industries

- BEVERAGE FILTER SUPPLIERS

- FABRIC LABELS

- AIR FILTRATION MANUFACTURING

- POOL AND SPA FILTER MANUFACTURING

- FIBER GLASS SCRIM BACKING

- BATTERY SEPERATORS

- COMPOSITES

- DRYER SHEET MANUFACTURING

- LIQUID FILTRATION (COOLANTS, LUBRICANTS, ETC) DESIGN

- LARGE FORMAT PRINTING FOR SIGNS AND ADVERTISING

- SUPPORT LAYES FOR COMPOSITES AND NANO COATING

- SUBSTRATES FOR FOAM TREATMENT, LAMINATION AND COATING

- INTERIOR SURFACES (INTERIOR TRIMS, SEATING, MOULD PARTS, TRUNK LINERS

To learn more about Bicomponent Fabrics here is a link to more information:

Bicomponent Fibers: Types, Manufacturing, Aftertreatment and Application @Textile Llearner.com

For a quote on your Bicomponent Fabric Manufacturing needs – contact Mogul Nonwovens today!