CANADIAN MELTBLOWN MANUFACTURING

Meltblown Technology is used to create filters for Medical Masks, Air Fitler Fabrics and much more.. Explore Mogul Canada’s line of Pure PP, PBT, PE, PLA, and TPU for Superior Quality and Versatility in your Meltblown filtration project.

MELTBLOWN PP FILTRATION

(Polypropylene) Advanced Fabric Technology

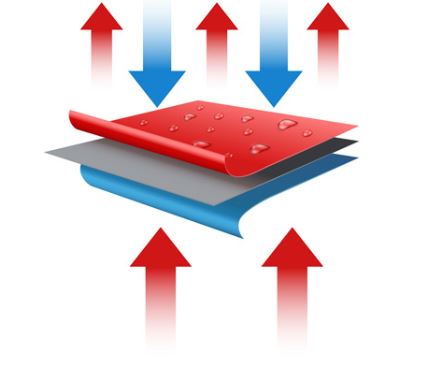

Mogul Canada stands out as a leading supplier of meltblown and SMS fabrics on a global scale. Meltblown, a polymer-based innovation, employs high-velocity air to attenuate extruded fibers, achieving a level of fineness beyond that of spunbond. These ultra-fine fibers boast an exceptionally large surface area, making them ideal for diverse applications, particularly in filtration.

Mogul Canada offers a range of meltblown fabrics, from monolithic options to composite fabrics featuring spunbond layers on one side (SM) or both sides (SMS) of the meltblown. The inclusion of spunbond layers enhances strength, catering to critical applications like medical and high-efficiency filtration.

Expanding beyond polypropylene (PP) meltblown, Mogul Canada also manufactures PBT (polybutylene terephthalate) and thermoplastic polyurethane (TPU) meltblown fabrics. PBT is chosen for filtration scenarios requiring resistance to chemicals and high temperatures, while TPU, derived from polyester, offers impressive compression set, elasticity, and resilience, making it perfect for stretching applications.

Mogul’s Canada’s Meltblown Fabrics find versatile use in:

- PP MELTBLOWN MEDICAL FACE MASKS ATSM LEVELS 1, 2, 3

- AIR FILTRATION MEDIA

- DRY-HOUSEHOLD WIPES

- NON-WOVEN SUPPORT LAYERS FOR COMPOSITES AND NANO COATING

Explore the forefront of meltblown fabric technology with Mogul Canada’s diversified meltblown solutions.

MELTBLOWN for MEDICAL MASKS PRODUCTION

Many companies in Canada are looking for new suppliers for Medical Mask manufacturing. Mogul Canada supplies a complete line of ASTM F2100 Level 3 medical face mask materials for your production line.

Explore Mogul Motex’s medical mask fabrics, ranging from 20-25gsm in classic Blue and White colors. These masks come in hydrophobic or hydrophilic options, with electro-statically charged meltblown for superior filtration capabilities.

| MOTEX PP | MOTEX PP | MOTEX |

| Polypropelene Spunbond | Polypropelene Spunbond | Pure Meltblown |

| Weight: 20 gsm | Weight: 25 gsm | Weight: 30 gsm |

| Construction: Spunbond | Construction: Spunbond | Construction: Meltblown |

| Composition: 100%PP | Composition: 100%PP | Composition: 100%PP |

| Color: Neutral white | Color: Blue (D5) | Color: Neutral White |

| Treatment: None | Treatment: None | Treatment: Electrostatic charge |

| Width: 19.5 cm | Width: 17.5 cm | Width: 17.5 cm |

| Core: 3’’ | Core: 3’’ | Core:3’’ |

Enhanced Electric Charging of Melt-Blown Nonwoven Filters for Superior Filtration Efficiency

Electrostatic charged Meltblown is particularly good in capturing nano-particles, while maintaining a low pressure drop. It is very important for nano particle engineers, manufacturing engineers, and face mask manufacturers who aim to develop more effective filtration systems without compromising on air pressure or breathability.

Electrostatic charging of meltblown Non-woven filters

Electric charge enhanced filtration materials demonstrate a significant ability to capture fine particles, achieved through the electrostatic attraction filtration mechanism. This mechanism improves filtration efficiency without requiring an increase in pressure drop, which is essential for applications such as face masks where breath-ability is important.

Exposing the filter material to a high-voltage corona discharge imparts electrostatic charges to the fibers. As a result, the charged fibers can attract and capture particles more effectively.

Research demonstrates that filters charged using the corona method outperform traditional mechanical filters. These charged filters maintain a low pressure drop, meaning they do not significantly impede airflow while still enhancing filtration efficiency.

The use of electrostatic materials can lead to better protection against airborne particles, including pathogens, without compromising user comfort.

For detailed insights and further information, you can read the full article here.

CANADIAN MELTBLOWN PBT

Polybutylene Terephthalate (PBT)

Meltblown Fabrıcs

Meltblown manufacturing plays a crucial role in various filtration applications, thanks to the fine fibers that deliver exceptional filtration efficiency. In comparison to PP (polypropylene), PBT (polybutylene terephthalate) products stand out by enabling filtration at notably elevated operating temperatures. Additionally, PBT manufacturing exhibits robust resistance to organic solvents and fuels.

PBT is widely employed in the automotive and heavy equipment industries, serving as an ideal filter media for hot and aggressive hydrocarbon fuels and oils. Unlike PP, which tends to absorb hydrocarbons and swell, PBT performs admirably in hydrocarbon environments. Its applications extend to filtering lubricants, coolants, and gaseous substances like crankcase ventilation and coalescence filters for moisture removal. The elevated temperature rating makes PBT well-suited for bag house, furnace, and industrial hot air filtration.

Another noteworthy application of Mogul Canada’s PBT is in high-efficiency blood filtration, ensuring the removal of undesirable elements such as water, fats, salts, and enzymes. Mogul PBT also finds utility in chemical processes and laboratories where resistance to chemicals is crucial for liquid or gas filtration.

Mogul Canada’s PBT meltblown fabrics, known for their heavier weight, can be pleated, presenting opportunities for achieving higher filtration efficiency. Mogul positions its PBT product as a potential substitute for micro-glass filtration media, showcasing its versatility and performance in various filtration scenarios.

CANADIAN MELTBLOWN AND COMPOSITES

(SM, SMS AND MMM)

Discover Ultra-Fine Fibers: Meltblown, a High-Tech Polymer Process with Air Attenuation for Finer Threads than Spunbond

Explore the Cutting-Edge Meltblown Technology: Elevate your applications with Mogul’s globally acclaimed Meltblown and Meltblown/Spunbond composites. Our advanced polymer-based Meltblown process employs high-velocity air attenuation to produce threads finer than traditional Spunbond methods.

As a leading global supplier, Mogul Canada delivers exceptional monolithic Meltblown fabrics or composite fabrics, featuring Spunbond on one side (SM) or both sides (SMS) of the Meltblown. The added Spunbond layer enhances strength, making it ideal for critical applications such as medical or advanced filtration.

Beyond polypropylene (PP) Meltblown, Mogul Canada specializes in producing PBT (polybutylene terephthalate) and thermoplastic polyurethane (TPU) Meltblown fabrics. Choose PBT for chemical resistance and high-temperature applications, or opt for polyester-based TPU for stretching applications, offering elasticity, excellent compression set, and high resilience.

Mogul Canada’s Meltblown is widely recognized in filtration media, boasting a high surface area due to its 6-8 micron fibers. With extensive expertise, Mogul produces polypropylene (PP), polybutylene terephthalate (PBT), and Thermoplastic Polyurethane (TPU) in various weights.

Applications:

- Air Filtration including Medical Masks

- Vacuum Cleaner Dustbags

- Acoustic Insulation

- Wound Care (Tapes, Bandages)

- Garments, Sheets

- Bags (Promotional, Retail)

- Wet Wipes

- Roofing

- House Wrap

- Workwear

- Liquid Filtration (Coolants, Lubricants)

Experience the Mogul Canada advantage in ultra-fine fiber technology, transforming your products and applications with unmatched quality and performance